Co extrusion snacks machines

1. Description

Co extrusion snacks machines uses advanced extruding technology, through changing moulds and production technics to produce many kinds of popular snack food in the market. It has a agility scheme, strong adaptability, has gained good praise and agreement from public.

Corn puffed snacks food machine from feeding materials,extruding,drying,oil spraying,cooling to packaging are finished once time automatic.We fill the gap of the first-class food produced with extruded & infated technology.This processing line can produce all kind of inflating foodstuffs,rice bread,core snacks,crackers,gruels,breakfast cereals,and baby food and so on.The raw materials can be maize,rice or wheat flour,etc.

2. Raw materials: corn flour, wheat flour , rice powder, starch ect

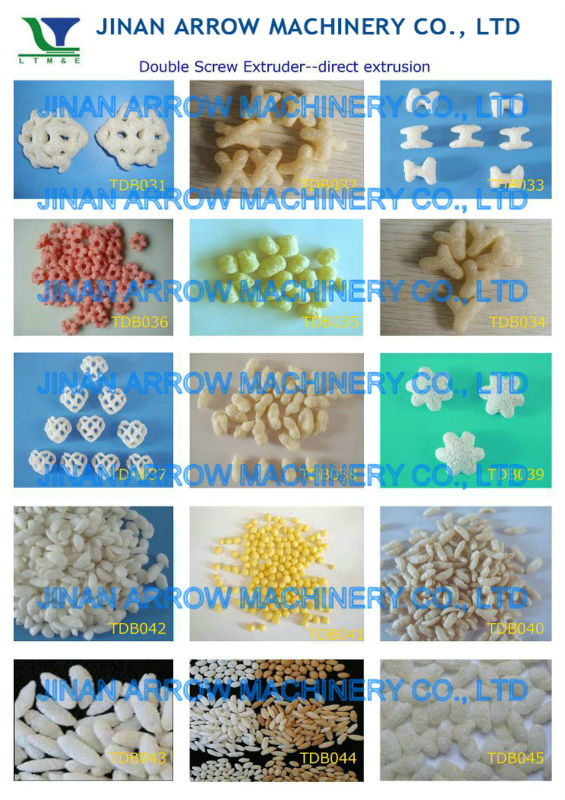

3. Products: all kinds of snacks with different shapes and types.

It includes cheese balls,corn curls,corn sticks,coco pops,cereal,kurkure and

4. Capacity: 120-150kg/h, 200-250kg/h,400-500kg/h

5. Flow chart: Mixing-Conveying-Extrusion-Drying--Flavoring line

The equipment list of Corn Cheese Snacks Sticks Machinery

Mixer-Screw Conveyor-Twin Screw Extruder-Air Conveyor-Multi-layer dryer-flavoring machine

6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

7. Machines Materials: All the machines are made BY SS

8. Technical Parameters

|

model

|

installed power

|

power consumption

|

output

|

size

|

|

AS65L

|

81.5kw

|

53kw

|

120--150kg/h

|

23000x1200x2200mm

|

|

AS70L

|

116kw

|

76kw

|

200-250kg/h

|

23000x1500x2200mm

|

|

AS85

|

181kw

|

117kw

|

400-500kg/h

|

28000x3500x4300mm

|

9.Service & Installation

a.) Consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

e.) Provide 1 year complete warranty and life-time maintenance service;

10. sample photo

11. Delivery

12.Service & Installation

a.) Consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

e.) Provide 1 year complete warranty and life-time maintenance service;

13. Our prestigious reputation got form the world: