Pufuleti Gusto Machines

1.Description

2.Technical parameter

|

Model

|

LT 85-II

|

|

Capacity

|

500 kg/h

|

|

Main motor

|

90 kw

|

|

Oil circle pump

|

0.37 kw

|

|

The pre-conditioner powe

|

4kW

|

|

Feeding Material Moto

|

0.75 kw

|

|

Rotary Cutting Moto

|

0.75kW

|

|

Heating Motor

|

22 kW

|

|

Power Installed

|

118kW

|

|

Voltage/Frequency

|

380V, 50Hz three phase

|

|

Screw Diamete

|

85 mm

|

|

Die hole specifications

|

Φ 1.5-Φ15mm

|

|

Extrusion rate

|

100%

|

|

Material of Screw

|

38CrMoAl

|

|

Material of barrel

|

40CrMoAl

|

|

Power consumption

|

65 kW

|

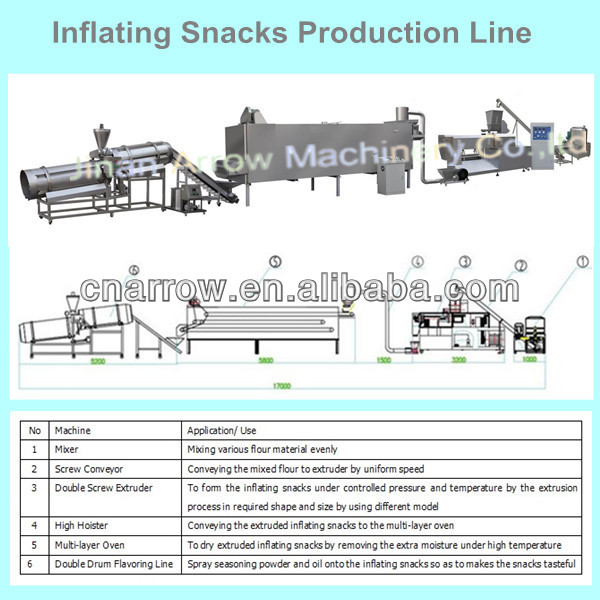

3.Cheese puffs/Corn puffs/Snacks food machines

1. The extruders are used in the production of many direct expanded snack and cereal. In such a cereal line, the dry ingredients are blended in a mixer and metered into the extruder along with the liquid ingredients.

2. The extruder is subjected to heat and shear to optimise the starch conversion according to the quality profile of the final product. Processing temperatures are precisely regulated through individual heating and cooling systems in each section of the extruder barrel.

Expansion takes place when the water in the extruder flashes off as the product is forced through the die.

3. The product shape is determined by a combination of the die aperture, expansion and the die cutter.

4. The product enters a belt dryer which reduces and stabilizes the moisture content. If a sweetened cereal is desired, the product may enter a coating unit for a liquid confectionery application, followed by a final drying procedure before packaging

4.Brief Introduction

Puff snack food making line is a new type of extruding food machine studied and developed on the basis of learning from advanced technology in the world .the line will finish mixing, extruding, shaping, roasting, spraying and proucing in one-pass opereation automatically.the line features lots of types, flexible collocation, extensive materials, various prodcuts and easy operation.

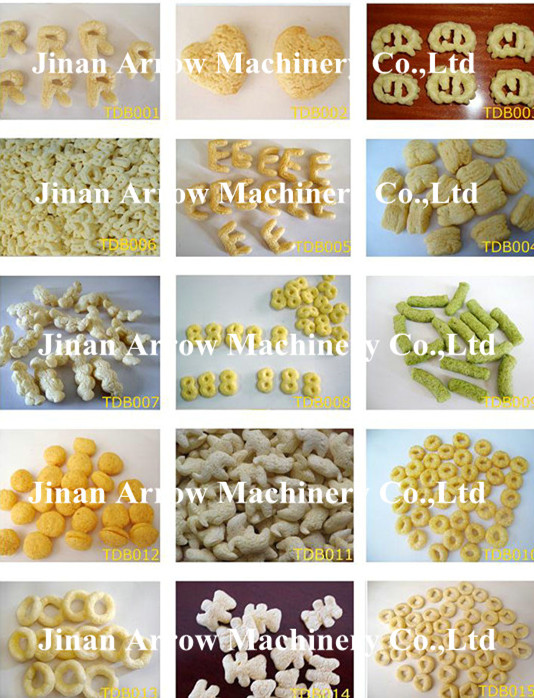

5.Puffing snacks

6. Core filling snacks

7.We Provide Satisfied Service & Turnkey Solution

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

8. Packaging

9. Company Information

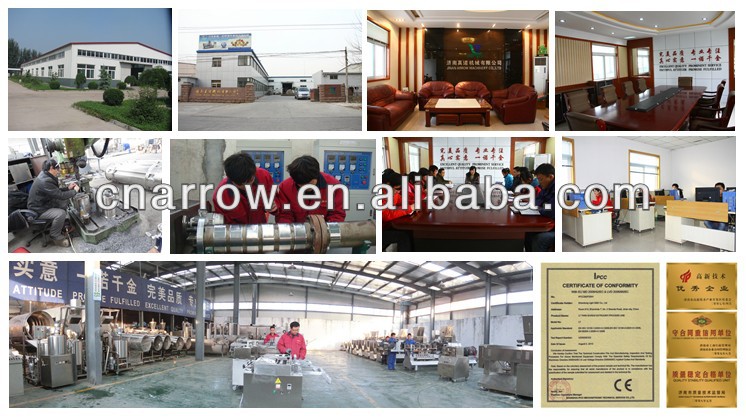

1. Company Image

2. Participating Exhibition

3. Visitors

4. Glories of Company

5. Cooperative Clients

6. World Market