Dog, Cat, Fish, Bird Food Machine

1. Description

Dog, Cat, Fish, Bird Food Machine can be classified into dog food machine, cat food machine, and bird food machine, etc.

Dog, Cat, Fish, Bird Food Machine uses materials like foodstuff, meat powder, fishmeal, and beans, etc. to produce fish and bird feed, etc. which usually come with different types, unique taste and rich nutrition. All types of animal food are provided with high temperature and high pressure processing in food extruders, which ensures high sanitation standard. Our dog food machine, cat food machine and fish food machine, etc. are ideal machinery for making pet feeds. We welcome worldwide pet feed producers to contact us for more information.

2.Parameters

| NO. |

Extruder Model |

Capacity |

Fryer/Dryer Fuel |

Area Requirement |

| 1 |

LT65 (L) |

120-150kg/hr |

Electric/Gas/Diesel/LPG |

17000*5000*3000mm |

| 2 |

LT70 (L) |

220-260kg/hr |

Electric/Gas/Diesel/LPG |

17000*5000*3000mm |

| 3 |

LT85 |

500kg/hr |

Electric/Gas/Diesel/LPG |

24000*5000*4000mm |

3.Our animal food machinery is composed of the following components, primarily.

1. Flour Mixer

2. Screw Conveyor

3. Twin Screw Extruder

4. Elevating Conveyor

5. Continuous Belt Oven

6. Double Drum Fat Coating Machine

4. Raw materials adopts corn flour, bone meal, fish meal as raw materials

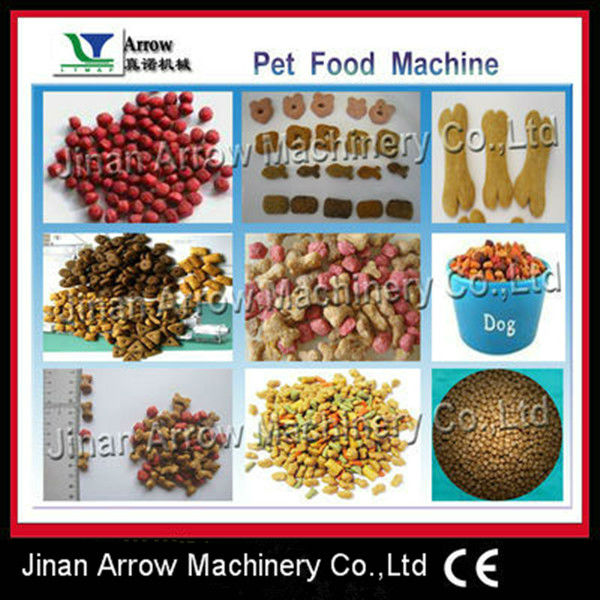

5. Products: different shapes are made by adjusting the dies from extruder

6. Capacity: 150kg/h, 240kg/h, 500kg/h, 800kg/h, 1ton/h, 2t/h,3ton/h,5t/h

7. Flow chart:Mixing system---Extrusion system----Drying system----Flavoring system--Packing system

8. Voltage

in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

9.Machines materials:

All the machines are made by stainless steel, this line is with reasonable design and with high automation; Mr.peter offer the screws are made by alloy steel, Light with building block system structure and self-cleaning function

10.Samle Pictures

11.The machines is possible to pack in wooden case or nude pack after wraping by plastic film.

12.Service & Turnkey Solution

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

13. Company Information

14. Glories of Company

15. World Market