snacks food machine

1. Description:

1. Snacks food machine can take corn, rice, wheat, oat, rye and other grains as materials to produce extruded snacks, with crispy taste and lively shape,

2. Snacks food processing line is designed according to market demand. It includes cheese balls, corn curls, corn sticks, cocopops, cereal, kukure and core filling food.

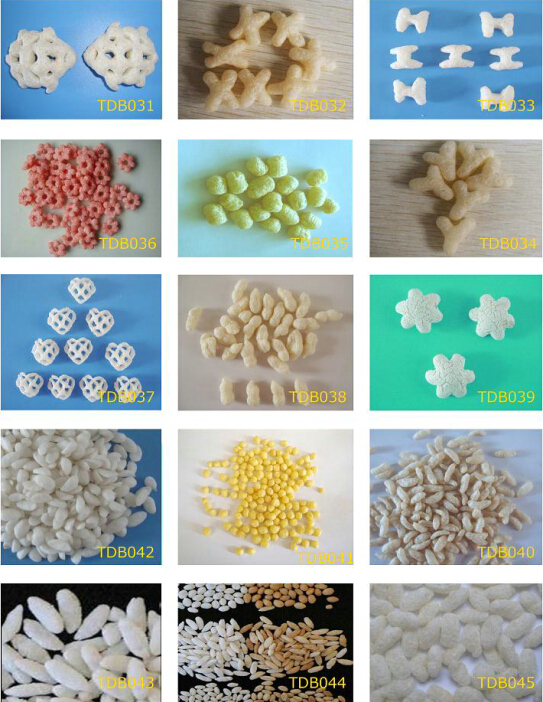

3. We can get different shapes: Round, triangle, square, stars, and flower

2.Technical parameter

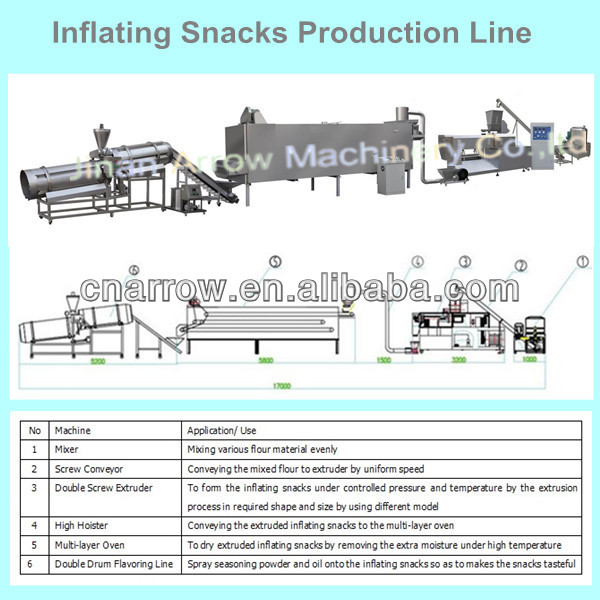

|

Model

|

LT 65L

|

|

Power

|

53KW

|

|

Main drive power

|

37KW

|

|

Heating power

|

14 kw

|

|

Feeding power

|

0.75 kw

|

|

Cutting powe

|

0.75 kw

|

|

Oil circle pump

|

0.37 kw

|

|

Length of screw(mm)

|

1.28M

|

|

Diameter of screw(mm)

|

65

|

|

Output

|

150-180kg/h

|

|

Dimension

|

3.4*0.93*2.1M

|

|

Applied products

|

Snacks\breakfast cereals

|

|

Main Feature

* Stainless steel is adopted as main material of extruder &controlling box shell plates

* Unique cooling water circulatory system.

* Lengthening screw with high quality

* High output

|

3. Raw materials: adopts corn, rice, wheat, oat, barley etc as ingredients

4. Products: Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder

5. Capacity: 150kg/h, 240kg/h, 500kg/h

6. Flow chart: Mixing system---Extrusion system---- -Drying system----Flavoring system---Packing system

7. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

8. Machines Materials: All the machines are made by stainless steel

9.Working Process of Corn Snacks Food Machine

10.Puffed Corn Snacks Samples

11.Strong Fumigation-Free Case or 20'GP or 40'HQ

Packed by wooden case or wrapped by plastic film then shipped by container.

12.Who We Are