2D/3D Snack Pellet Processing and Frying Machine

I. 2D/3D Snack Pellet Sample Pictures

II.Brief Introduction of 2D/3D Snack Pellet Processing and Frying Machine

2D/3D Snack Pellet Processing and Frying Machine is mainly used to produce all kinds of fried pellet snacks. Raw material can be potato starch, potato flakes, corn starch, wheat flour, cassava starch etc. Through the extruder cooking, the snacks can be shaped in shell,screw,spiral etc. Also, by changing the shaping machine, we can produce square tube,circle tube, wave chips,potato chips,shrimp chips etc and 3d pellet shapes like ball, polygon, pat, Christmas tree, heart, bugle etc. After drying and frying, flavoring with the seasoning powder, we can get delicious snacks food.

II. Technical Parameter of 2D/3D Snack Pellet Processing and Frying Machine

| Model |

Installed powder |

power consumption |

Capacity |

Dimension |

| FT75 |

100kw |

55kw |

250-300kg/h |

4400*1200*2100mm |

III. Why 2D/3D Snack Pellet Processing and Frying Machine is The Best Choice

1. The Screw is made of durable hard alloy-38CrMoAl, with quite long using life.

2. Feeding Hopper uses Two grades mixing design which allows high feed speed and also avoid any block in raw materials.

3. Radiating Windows design ensure the thermal heat caused by machine discharge easily to extend the machine using life.

4. SIEMENS(China) motors are used, ensure the excellent performance of machines.

5. Cooper Pipes used for cooling cylinder, they are quite durable than plastic rubber pipes.

6. Food Grade stainless steel made Cutter cover meet strict food process sa

V.Know More About 2D/3D Snack Pellet Processing and Frying Machine

VI.We Provide Satisfied Service & Turnkey Solution

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

VII.Strong Fumigation-Free Case or 20'GP or 40'HQ

Packed by plywood case or wrapped by plastic film then shipped by container.

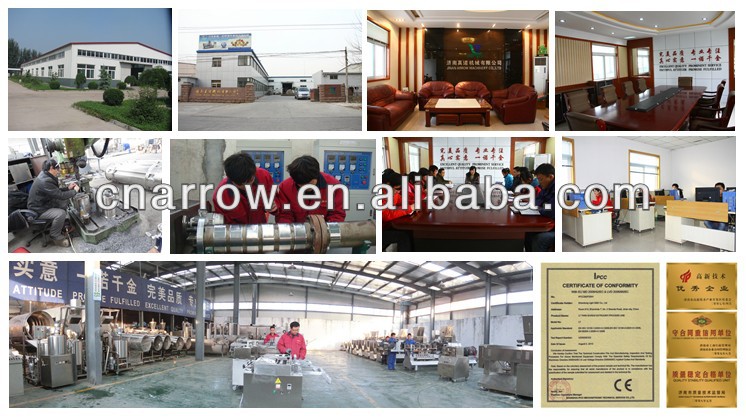

VIII.Who We Are

IX.Basic Company Information

We, Jinan Arrow Machinery Co., Ltd are located in the famous industry city-Jinan city, capital of Shandong Province;

Professional manufacturer of food extruders, mainly dealing with the manufacture, research, development and marketing of the puffing/inflating food machinery;

OEM service provided.

X.CE and ISO9001 Certificate

XI.Main Products List of our factory