Five layer oven

I.Introduction

These series of roasting oven are widely used for drying all kinds of stick, piece, grain etc. Shaping inflating snack food, the user can choose different types of dryer according to layer, length or energy.

II. Technical Parameters

|

Model

|

Electric(Gas/Diesel) Consumption

|

Heating Temperature

|

Output

|

Dimension

(L×W× H)

|

Applied Products

|

|

Three-layer

Electric Oven

|

30kw/h

|

180°C

|

150kg/h

|

5400x1300x2000mm

|

Puffed Snacks, Breakfast Cereals

|

|

Three-layer

Electric Oven(Longer)

|

45kw/h

|

180°C

|

250kg/h

|

7000x1600x2150mm

|

Puffed Snacks, Breakfast Cereals

|

|

Five-layer

Electric Oven

|

60kw/h

|

180°C

|

250kg/h

|

5800x1300x2400mm

|

Puffed Snacks, breakfast cereals

|

|

Three-layer

Gas/Diesel Oven

|

4.8-10 m³/h(gas)

5.1-10kg/x (diesel)

|

180°C

|

150kg/h

|

6500x1600x2000mm

|

Puffed snacks, breakfast cereals

|

|

Three-layer

Gas/Diesel Oven(Longer)

|

16-22 m³/h (gas)

7-14kg/x (diesel)

|

180°C

|

250kg/h

|

8000x1800x2150mm

|

Puffed snacks, breakfast cereals

|

|

Five-layer

Gas/Diesel Oven

|

16-22 m³/h (gas )

7-14kg/x (diesel)

|

180°C

|

250kg/h

|

6000x1500x2400mm

|

Puffed snacks, breakfast cereals

|

|

Seven-layer Dryer

|

48kw/h

|

90°C

|

200kg/h

|

9000x2400x3000mm

|

extruded pellets

|

|

Rotary Dryer

|

Electric :60kw/h

Gas/Diesel:BTG11 4.8-10m3/h

|

180°C

|

250kg/h

|

6500x1600x2000mm

|

Puffed snacks, breakfast cereals

|

III. Why We Are Your Best choice

1.food grade stainless steel mesh conveyor belt,free of damage to human body.

2.Drying temperature and time can be adjusted through the button on controller,capital drying effect;

3.World famous brand of electric parts,such as LG,FUJI,and Omron etc.

4.Various heating types are available, such as electric,gas,LPG,diesel and team.For non-electric type,Italian Baltur brand buner.

5.Insulated with aluminum silicate and exterior cover is 304 stainless steel.

6.For small granule,mesh cloth need to put on conveyor belt to avoid leakage from the mesh.

7.Different types of dryer can be made according to users'requirement based on layer,lenth,heating type,machine material etc.

IV. Products It can dry

V. Product Photo Show

VI. We Provide Satisfying Service & Turnkey Solution

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

e.) Provide 1 year complete warranty and life-time maintenance service.

VII. Strong Fumigation-Free Case or 20'GP or 40'HQ

The Machine is packed by wooden case or wrapped by plastic film and then shipped by container.

VIII. Our Reputation Is Got from the World

Clients Visiting Our Company

Our machines are exported to more than 90 countries and areas and got high praise of customers. Some of them have become our agents in their area. We hope to build more business relationship with clients all over the world.

Distribution of Our Clients In the World

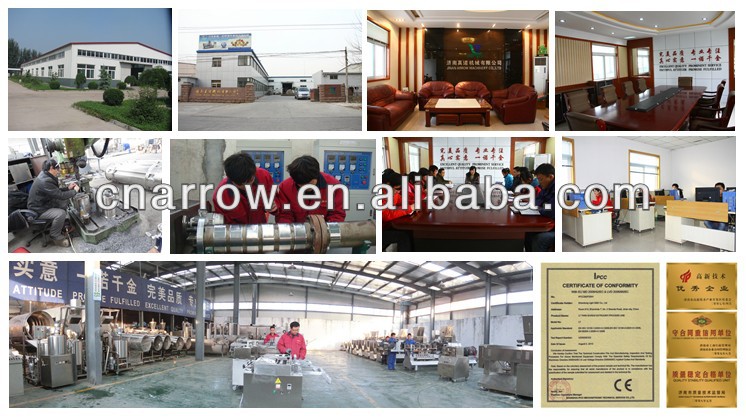

IX. About the Company

Our Company , Jinan Arrow Machinery Co., Ltd is located in the famous industry city, Jinan, the capital of Shandong Province,China.

We are professional manufacturer of food extruder and mainly deal with the manufacture, research and development of the inflating food machine. According to the clients’ different requirements, we can offer the whole complete processing line for all kinds of expanded snacks, corn flakes, nutrition powder, and pet food etc.

Participating in various exhibition

X. We are Certified

Since the establishment of our company, we have been manufacturing our machines according to the authorized standards, by now ,we have got several certificates, including CE and ISO9001 and we are 4 Years Alibaba Golden Supplier.