HTST extruder for Kurkure

1. Description:

Kurkure are extruded snacks, very crunchy and great in taste. Kurkure are made by extrusion process. The Kurkure corn meal is moisturized in the flour mixer with water and fed to the Rotary die Extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The Kurkure are fried in cooking oil and then cooled before flavoring. Seasoning is sprayed on the Kurkure to improve their taste.

Machines involved in making Kurkure:

a): Flour Mixer

To mix corn meal with water to prepare the flour for Kurkure

b): Rotary Die Extruder

To cook the corn meal and extrude the Kurkure from the die. The Rotary Die twists and curls the meal before extruding giving a uniform texture

c): Automatic Frying Machine

To fry the Kurkure in hot cooking oil. The uniform frying introduces the crunchy taste to the Kurkure

d) : Cooling Conveyor

To cool the fried Kurkure and reduce the temperature before packing

e): Automatic Seasoning System

To add required seasoning to the fried and cooled Kurkure to give the different flavors to them

f) : Automatic Packaging Machine

To pack the Kurkure into attractive printed pouches with gas flushing

2. Raw materials: corn grits

3. Products: kurkure/cheetos/Niknak with different tastes

4. Capacity: 125-140kg/h, 200-230kg/h

5. Flow chart: Fried type: Mixing ---Extrusion ----Separating ----Frying ---Flavoring

6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

7. Machines Materials: All the machines are made by 304 stainless

8. Technical Parameters

|

model

|

installed power

|

power consumption

|

output

|

size

|

|

LTTS-IF

|

96kw

|

62kw

|

125kg/h

|

17000x1100x2500mm

|

|

LTTS-IIF

|

98kw

|

63kw

|

200kg/h

|

17300x1200x2600mm

|

|

LTTS-IB

|

69.36kw

|

45kw

|

125kg/h

|

16000x1100x2500mm

|

|

LTTS-IIB

|

71.36kw

|

46.5kw

|

200kg/h

|

16300x1200x2600mm

|

9.Why We Are The Best Choice

1. Blower to ensure discharge products faster and unblocked,

2. Window on the Hopper to check the raw materials level and quantity easily,

3. Vibrant Motor on the Hopper ensure feed raw materials fast and successfully,

4. Inverters, Conductors and other electronic parts are from World-famous Brands, like FUJI, LG, DELTA.

5. Main Motors are from SIEMENS(CHINA), ensure strong and excellent performance.

10.Know More About Cheetos Corn Snack Making Machine

11.Product photos Fully Automatic Industrial Extruded Kurkure Processing Machinery

12.We Provide Satisfied Service & Turnkey Solution

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

13. Packaging

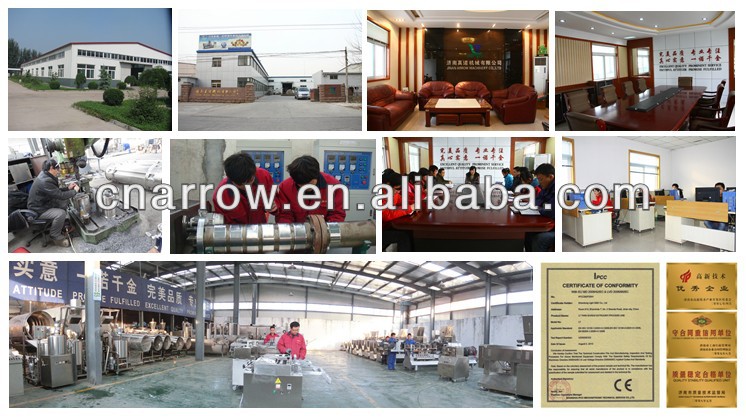

14. Company Information

1. Company Image

2. Participating Exhibition

3. Visitors

4. Glories of Company

5. Cooperative Clients

6. World Market