artificial nutrition rice machine

1.Descripton

The traditional rice processing leads to loss of nutrional elements in the rice. Rice and rice by-products can be used to produce novel foods with additional value by extrusion cooking. For this process, mainly broken rice and rice bran are being used. Process for making reconstituted rice grains, comprising cooking a mixture of rice flour, water and hydrogenated oil in a cooker-extruder, to produce a partly gelatinized mixture, forming the partly gelatinized mixture into rice-grain shaped pieces and drying and cooling the pieces to room temperature to provide the reconstituted rice grains. Some nutrition factors can be nozzled in this process to make it enriched rice.

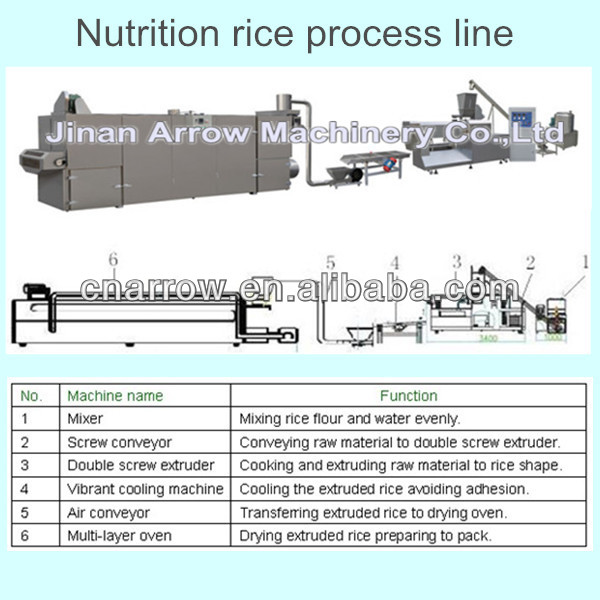

artificail nutrition rice machine Flow Chart:

2.Brief Introduction

This Nutritional Rice Machine is studied in concern with the loss of nutritional elements in the rice which is made by the traditional rice processing. Rice and it's by-products can be produced into highly nutritional foods by adding additional nutrient components after extrusion cooking. Further, for this process, the broken rice and rice bran can be reused. Process for making artificial rice grains,comprises a mixture of rice flour,water and oil in the extruder, forming into rice-grain shape,drying and cooling in low temperature.The technology makes it feasible to avoid the loss of nutrition.

3.Technical Parameters

| model |

installed power |

power consumption |

output |

size |

| LT65L |

84kw |

59kw |

180kg/h |

14000*1200*2200mm |

| LT70L |

120kw |

84kw |

200-250kg/h |

16000*1500*2200mm |

| LT85 |

225kw |

158kw |

500-700kg/h |

20000*3500*4300mm |

| A85 |

243kw |

170kw |

800-1000kg/h |

20000*3500*4300mm |

4.Sample Pictures

5.Know more

6.Service & Turnkey Solution

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

7. Company Image

8. Glories of Company

9.World Market