food machine /breakfast cereals machinery

Description

food machine /breakfast cereals machineryuses corn as raw material.It can be mixed with coffee or milk, or eaten as snacks.

food machine/breakfast cereals machinery use corn and other cereals as main material, through mixing,extruding or boiling, planishing, drying, baking, coating and cooling, to get crispy flakes. It can be mixed with coffee or milk, or eaten as snacks.

snacks food machinery /breakfast cereals machineryis developed and manufactured on the basis of the international advanced extruder technology, which is named corn flakes breakfast processing line. Its technology performance and quality can reach international advanced level. This line consist of mixing, boiling, pressing, drying and inflating, which can be finished in one time, the level of its automation is very high.

1. Introduction

Corn flakes (Breakfast Cereals) is the most popular breakfast cereals in the world. It is a perfect cereal because of the crispy taste. Our corn flakes production lines are based on extrusion technology which is so widely used in food industry.

2. Technical parameter

| Extruder Model |

LT65 |

LT70 |

LT85 |

| Capacity |

120kg/h |

200kg/h |

300kg/h |

| Dryer/Fryer Fuel |

Electric/Gas/Diesel/LPG |

Electric/Gas/Diesel/LPG |

Electric/Gas/Diesel/LPG |

| AreaRequirement |

40000*5000*3000mm |

42000*5000*3000mm |

50000*5000*3000mm |

| Raw Material |

Corn Grits (Powder), wheat flour, rice flour, oat meal, other grain meals |

| Flow Chart |

Flour mixing - Extrusion - Flaking - Drying - Roasting|Baking - Sugar Coating - Drying - Packing |

3. Equipments Components

Flour Mixer | Screw Conveyor |Twin Screw Extruder| Air Conveyor | Flaking Machine | Air Conveyor | Continuous Belt Dryer | Elevating Conveyor | Vibrating Feeder | Baking Machine | Air Conveyor | Sugar Coating Machine | Extended Continuous Belt Dryer | Cooling Conveyor

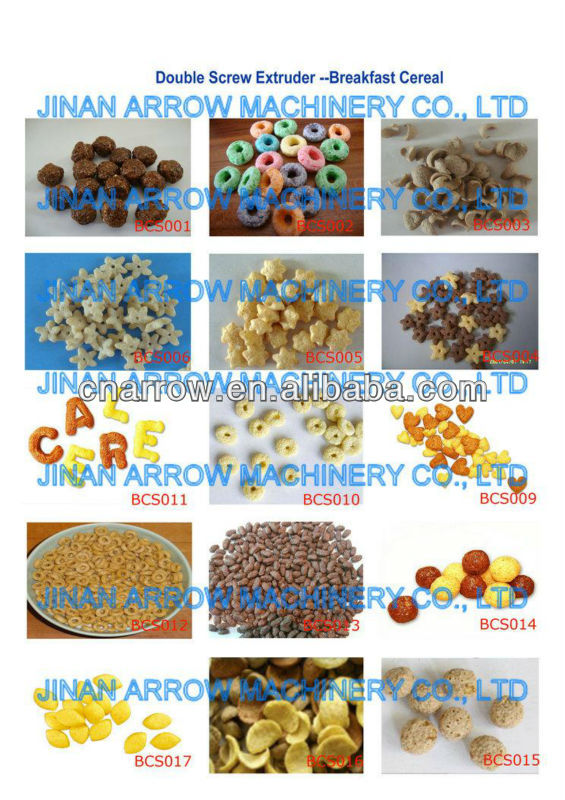

4. Sample pictures

5. Production

a.) Design: All the machines are elaborately designed by our mechanical engineers who are rich of experience in this field. We accept special design according to customer’s request.

b.) Processing & Assembling: Parts processing, assembly, testing are based on standard test.

c.) Trial Run: Each machine has to be tested before its deliver.

6. Delivery

The machines is possible to pack in wooden case or nude pack after wrapped by plastic film.

7. Service & Installation

a.) Consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

e.) Provide 1 year complete warranty and life-time maintenance service