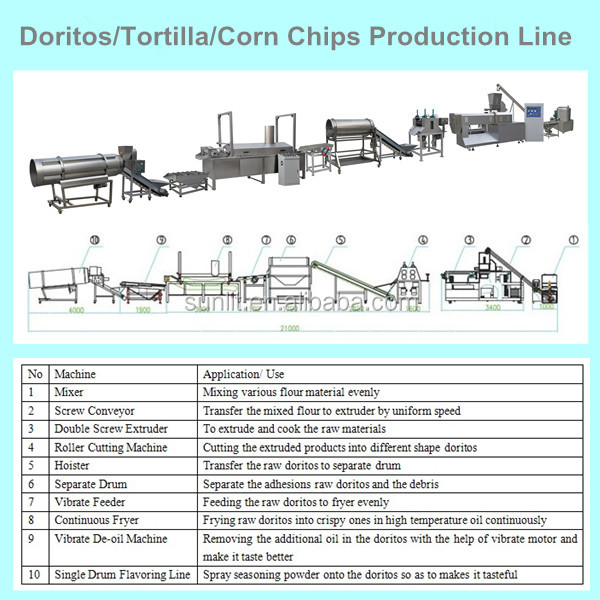

Doritos Chips Machine

I. Description

Doritos/Tortilla/Corn chips are kinds of snacks made from corn powder, which are cut and then fried. The main raw materials are corn powder, vegetable oil, salt and water. Although usually made of yellow corn(as pictured), they also can be made of white or red corn. After frying and flavoring, we get very crunchy triangle or other shapes chips, which are popular with both children and adult.

1. Raw Materials: Corn Powder as Usual

2. Products: All shapes of Doritos, shapes like round, triangle, hexagon etc. The size of products can be changed according to clients’ requirements.

3. Capacity: 120-150 KG/H, 200-250 KG/H

4. Flow Chart: Mixing—Extrusion —Shaping —Separating—Frying/Baking —Flavoring

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage of different countries.

6. Machines Materials: All the machines are made by food grade stainless steel

II. Sample Picture

III. Details & Features

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

2. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine guarantees stable materials feeding in the whole food process.

3. The gearbox has automatic lubrication function, with extends gear life.

4. Radiator is increased on driving part for forced cooling effect, and it ensures extruder operate safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

IV. Flow chart

V. Technical Parameters

| Model |

Installed Power |

Power Consumption |

Output |

Size(L×W× H) |

| LT65 |

143kw |

100kw |

120-150kg/h |

22000x1200x2200mm |

| LT70 |

187kw |

131kw |

200-250kg/h |

24000x1500x2200mm |

VI. Packaging & Shippping

VII. Service & Turnkey Solution

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

VIII. Company Image

IX. Glories of Company

X. World Market