Dog Biscuit Production Line

I.Brife Introduction

Dog Biscuit Production Line is equiped with Modular Circular Groove Screw completely different from traditional type, mainly used to produce all kinds of pet food by changing screw assembling sequence,such as dog,cat,fish,bird,bear etc

II. Technical Parameters

|

Model

|

main motor Power

|

Output

|

Size

|

|

A85

|

55kw

|

800-1200kg/h

|

4400*3400*2350mm

|

III.Details and Features

1. Big Capacity Feeding Hopper, Variable Frequency Speed, Two Stages Mixing Wings ensure the Fast and Efficient Mixing and Feeding.

2. Double Axis Differential Conditioner, Available for Steam, Pre-cooking and High Efficient.

3. Linear Slide Face Cutting System, Strong Power, Variable Frequency Speed and Large Output,

4. Unique Designed Square Barrels, Made by Hard Carbide Sleeve, Hard-wearing and Durable.

5. Modular Circular Groove Screws, available for Different Extrusion Rate Applications.

6. Steam Heating System, ensure the Most Efficient, Continuous and Stable Heating Effects.

7. World-famous Brands Electronic Apparatus used in the Controller Box, make sure the Extrusion Process Perfect.

8. Main Motor from SIEMENS(CHINA), 90KW, ensure its Powerful Extrusion and Excellent Performance.

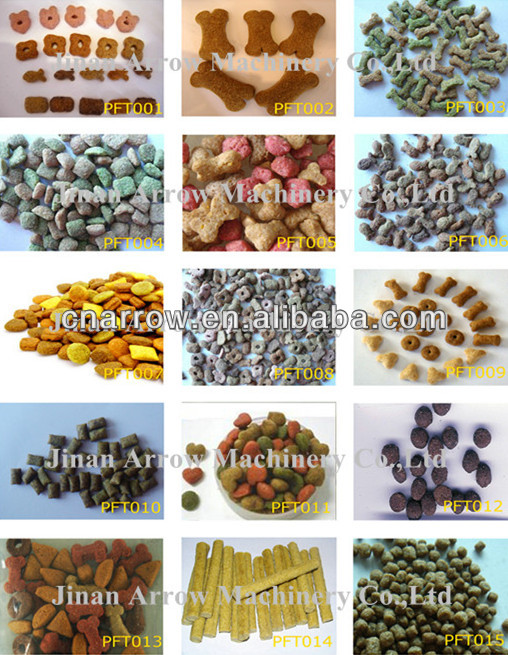

IV Sample Pictures

V. Know More

VI.Different type and capacity of Dog Biscuit Production Line

VII.Strong fumigation free case or 20’GP or 40’HQ

The machines is possible to pack in wooden case or nude pack after wraping by plastic film.

VIII.Service & Turnkey Solution

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

IX.Company Information

X.Glories of Company

XI.World Market