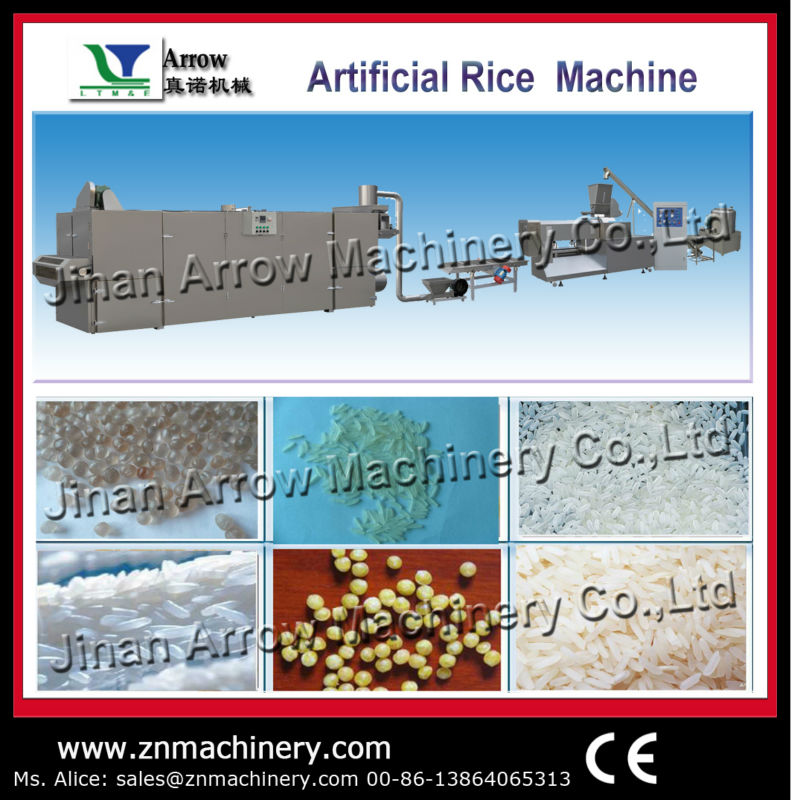

Puffed Food Machine Extruder Ireconstituted Nutrition Rice Processing Line

1. Introduction OF Puffed Food Machine Extruder Ireconstituted Nutrition Rice Processing Line

Puffed Food Machine Extruder Ireconstituted Nutrition Rice Processing Line is studied in concern with the loss of nutritional elements in the rice which is made by the traditional rice processing. Rice and its by-products can be produced into highly nutritional foods by adding additional nutrient components after extrusion cooking. Further, for this process, the broken rice and rice bran can be reused. Process for making artificial rice grains, comprises a mixture of rice flour, water and oil in extruder, forming into rice-grain shape, drying and cooling in low temperature. The technique makes it feasible to avoid the loss of nutrition.

2. Raw Material

Rice powder

3. Flow Chart

Our company has rich experiences in this field. We are able to supply turnkey project including grinding system for raw material, production machines for food, packing system for final products, even other lab testing equipments, etc.

Flour Mixing – Extrusion – Drying

4. Different Models High yield enriched rice machine for your choice

|

model

|

installed power

|

power consumption

|

output

|

size

|

|

AS65L

|

66kw

|

50kw

|

100-120kg/h

|

14000x1200x2200mm

|

|

AS70L

|

100kw

|

67kw

|

150-200kg/h

|

16000x1500x2200mm

|

|

AS85

|

130kw

|

80kw

|

300kg/h

|

20000x3500x4300mm

|

5. Equipments Components

Flour Mixer|Screw Conveyor|Twin Screw Extruder | Elevating Conveyor|Continuous Belt Dryer

6. Other nutrition rice/artificial rice is Possible for Puffed Food Machine Extruder Ireconstituted Nutrition Rice Processing Line

7. Production

a.) Design: All the machines are elaborately designed by our mechanical engineers who are rich of experience in this field. We accept special design according to customer’s request.

b.) Processing & Assembling: Parts processing, assembly, testing are based on standard test.

c.) Trial Run: Each machine has to be tested before its deliver.

8. Delivery

The machines is possible to pack in wooden case or nude pack after wraping by plastic film.

9. Service & Installation

a.) Consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service;