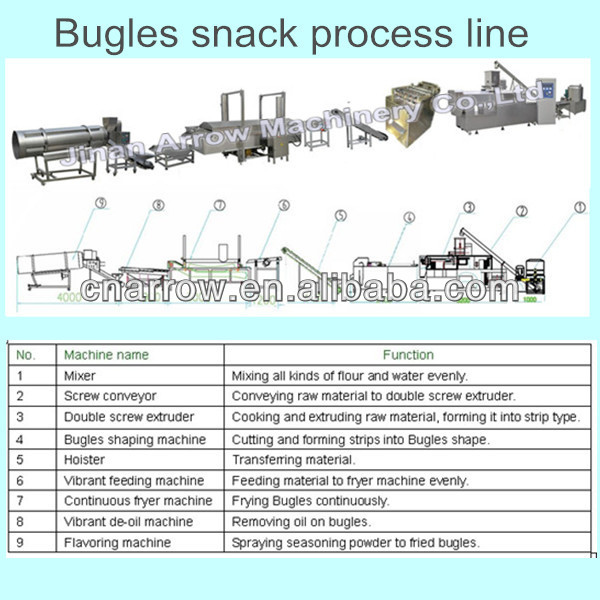

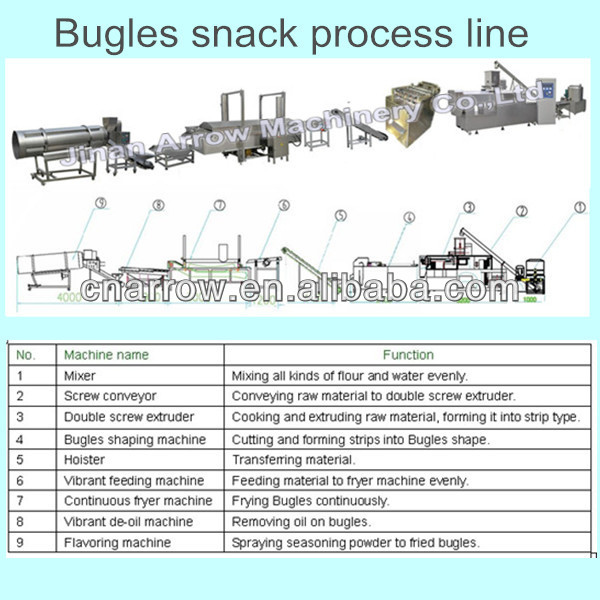

Product Description

Fried tube snacks machine

I. Brief Introduction

The process line uses double screw extruding technique to replace the traditional steam boiling process. It includes mixing,cooking,extruding and shaping process, no needing boiler, with simple process, high efficiency and little pollution. The raw materials can be rice powder, corn powder, wheat flour individually or their mixture. Only by changing the moulds, shaping or cutting machine, the shapes can be various, like sticks, square sheet rib chips, diamond chips, wavy chips, pillow shapes and bugles etc. the taste is good and also without greasiness.

II. Technical Parameters

| model |

installed power |

power consumption |

output |

size |

| LT65 |

141kw |

85kw |

120--150kg/h |

22000x1200x2200mm |

| LT70 |

160kw |

96kw |

200-250kg/h |

24000x1500x2200mm |

III. Why We Are The Best Choice

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. World famous brand Siemens main motor, guaranteeing good quality

5. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

IV. Bugle chips Sample Pictures

V. Know more about fried bugle chips making machine

VI. We Provide Satisfied Service & Turnkey Solution

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

VII. Strong Fumigation-Free Case or 20'GP or 40'HQ

Packed by wooden case or wrapped by plastic film then shipped by container.

VIII. Our Prestigious Reputation Got from the World

Clients visiting our factory

Our machines are exported to more than 90 countries and areas and got high praise of customers. Some of them have become our agents in their area. We hope to hold long friendly business relationship with more clients all over the world in the future.

Distribution of our clients in the world

Part of clients list

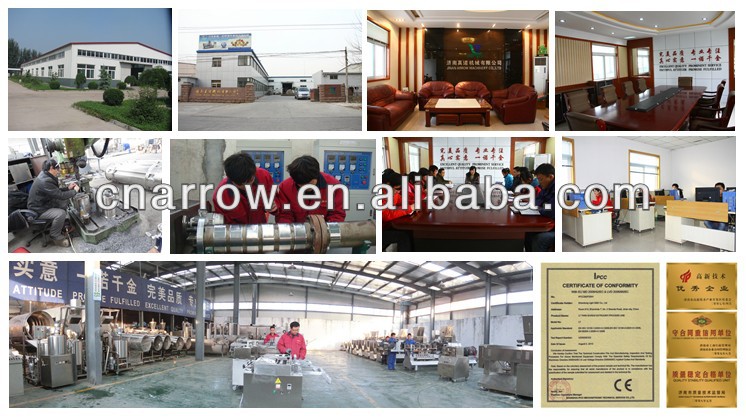

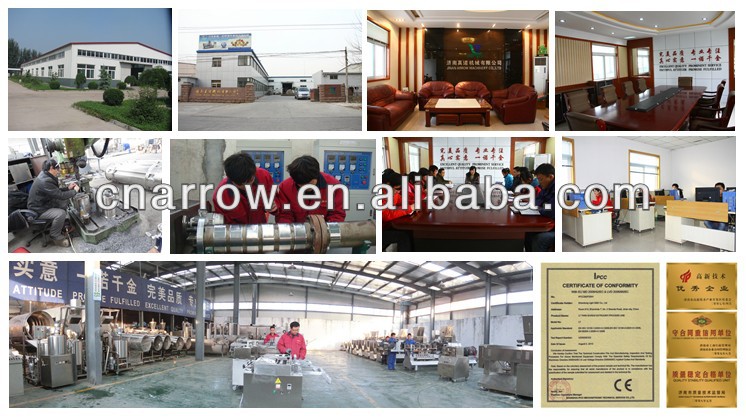

IX. Who We Are

We, Jinan Arrow Machinery Co., Ltd are located in the famous industry city-Jinan city, capital of Shandong Province.

We are professional manufacturer of food extruder and mainly deal with the manufacture, research and development of the inflating food machine. According to the clients’ different requirements, we could offer the whole complete processing line for all kinds of expanded snacks, corn flakes, nutrition powder, and pet food and so on. Our technical assistance will help clients produce high quality products all the time. Depending on our rich experience and professional experts on the extruded food industry, we could offer the most suitable and complete program to assure that your investment will get biggest profit.

Participating in various exhibition

X. We are Reliable and Certified

Since the establishment of our company, we have always manufacturing our machines according to the authorized standards, by now ,we have got several certificates including CE and ISO9001 and we are 4 Years Alibaba Golden Supplier.